Advanced Production Techniques: In-Mold Decorations Explained

Advanced Production Techniques: In-Mold Decorations Explained

Blog Article

In-Mold Decorations Demystified: Unlocking the Keys Behind This Cutting-Edge Manufacturing Process

In today's busy production landscape, in-mold decorations have emerged as a sophisticated strategy that proceeds to intrigue industry professionals. Stay tuned as we study the underlying principles and unveil the enigmatic allure of in-mold designs, losing light on the tricks that drive this procedure to the forefront of contemporary manufacturing methodologies.

The Development of In-Mold Decorations

The advancement of in-mold decorations has actually been marked by significant advancements in technology and layout technology. In-mold designs were restricted in their complexity and shade choices. Nonetheless, with the advent of new manufacturing strategies and materials, the possibilities have increased tremendously.

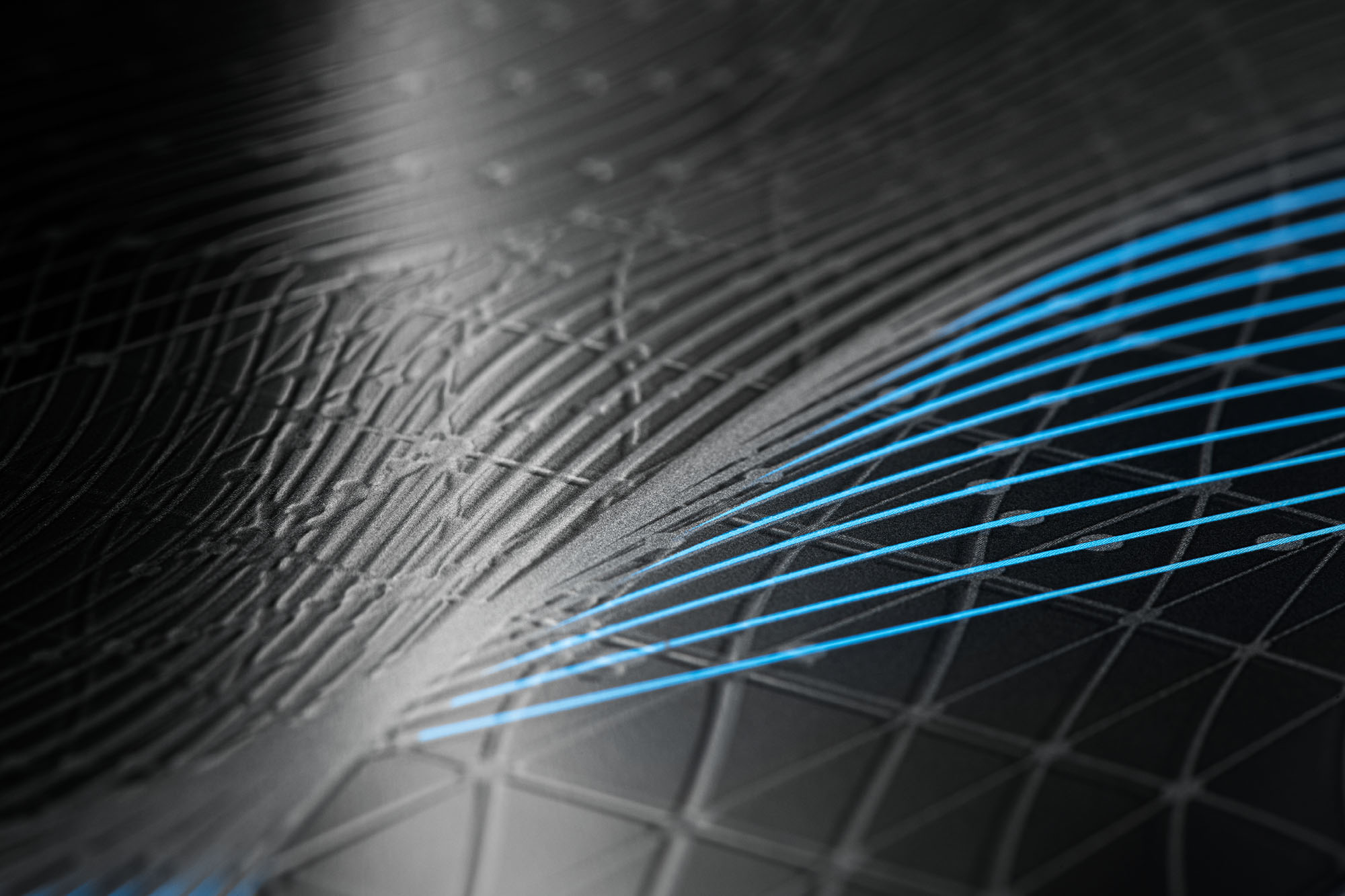

One trick development has been the growth of high-resolution printing processes that enable for intricate layouts with dynamic colors to be moved onto products throughout the molding procedure. This has allowed manufacturers to attain photorealistic photos and thorough graphics that were previously unattainable.

Additionally, the combination of robotics and automation in the in-mold design procedure has actually enhanced performance and uniformity in using designs to items. This not just reduces manufacturing time yet also improves the overall high quality of the finished items.

Understanding the In-Mold Refine

Marked by substantial innovations in modern technology and style innovation, the evolution of in-mold designs has led the way for a much deeper understanding of the detailed process involved in producing these decorative components. The in-mold process is an advanced production technique where ornamental aspects are incorporated straight into the final product throughout the molding process. This method includes positioning a pre-designed design, such as a graphic or tag, right into the mold cavity prior to infusing the product. As the material streams right into the mold, it bonds with the design, causing a smooth integration of the style into the item.

Understanding the in-mold process needs precise control over various criteria, including timing, temperature level, and stress, to guarantee the decor adheres properly to the product. In addition, picking the best products is crucial to achieving top notch outcomes. By grasping the complexities of the in-mold process, makers can generate visually striking items with resilient, lasting decors that enhance both the aesthetics and performance of the end product.

Benefits of In-Mold Decorations

Progressing item looks and sturdiness, in-mold designs offer a structured technique to incorporating attractive elements throughout the production process. One of the crucial benefits of in-mold decorations is the click to find out more smooth combination of shades, appearances, and graphics directly right into the product throughout the molding procedure. In-Mold Decorations. This eliminates the demand for post-production decor methods, such as painting or printing, which can be taxing and pricey

In addition, in-mold decors are extremely long lasting as the graphics are enveloped within the product, making them immune to put on, scrapes, and fading. This leads to products that maintain their aesthetic appeal and branding for a longer duration, also in severe settings.

In addition to enhancing aesthetic appeals and toughness, in-mold designs also supply enhanced design versatility. Makers can quickly integrate complex layouts, structures, and branding aspects that would be impossible or difficult to attain with standard design methods.

Applications Throughout Industries

Across various industries, in-mold decors have actually discovered functional applications that enhance both the visual allure and sturdiness of products. In the automobile market, in-mold decors are typically utilized for interior trim parts, such as facility consoles and door panels, offering a top quality finish that is immune to scratches and fading. The consumer electronic devices market gain from in-mold decorations on things like smartphone situations and laptop covers, where intricate layouts can be effortlessly incorporated right into the manufacturing process. In addition, the home appliance industry uses in-mold designs to develop resilient and stylish control board and fascia for items like stoves and fridges. In the toy market, in-mold designs are used to include in-depth graphics and vibrant colors to plastic toys, making certain a child-friendly and aesthetically enticing appearance. On the whole, in-mold decors offer a affordable and efficient way to improve the appearances and durability of products throughout a variety of sectors - In-Mold Decorations.

Future Patterns in In-Mold Innovation

The evolution of in-mold decorations is positioned to proceed shaping the landscape of item layout and production as Future Trends in In-Mold Modern technology guarantee cutting-edge options to even more boost visual aesthetic appeals and item toughness. In addition, developments in electronic printing strategies are enabling producers to achieve greater modification and information in in-mold decors, opening up brand-new possibilities for imaginative product layouts. Another significant fad is the assimilation of smart innovations, such as NFC tags or about his LED lighting, straight right into in-mold designs, including interactive and practical elements to products.

Verdict

In-mold decorations have changed the manufacturing procedure by effortlessly integrating style components right into items. With its various advantages and versatile applications across different markets, in-mold technology is poised to proceed forming the future and evolving of manufacturing.

By grasping the complexities of the in-mold procedure, suppliers can generate aesthetically striking products with long lasting, lasting decorations that enhance both the appearances and capability of the last product.

Progressing product visual appeals and longevity, in-mold decorations supply a structured technique to integrating attractive aspects during the manufacturing process. One of the key advantages of in-mold designs is the smooth assimilation of graphics, structures, and colors straight right into the item during the molding procedure.The advancement of in-mold designs is positioned to proceed forming the landscape of product design and manufacturing as Future Trends in In-Mold Innovation guarantee innovative solutions to additionally enhance aesthetic aesthetics and item longevity.In-mold designs have actually changed the description manufacturing process by flawlessly incorporating layout elements into products.

Report this page